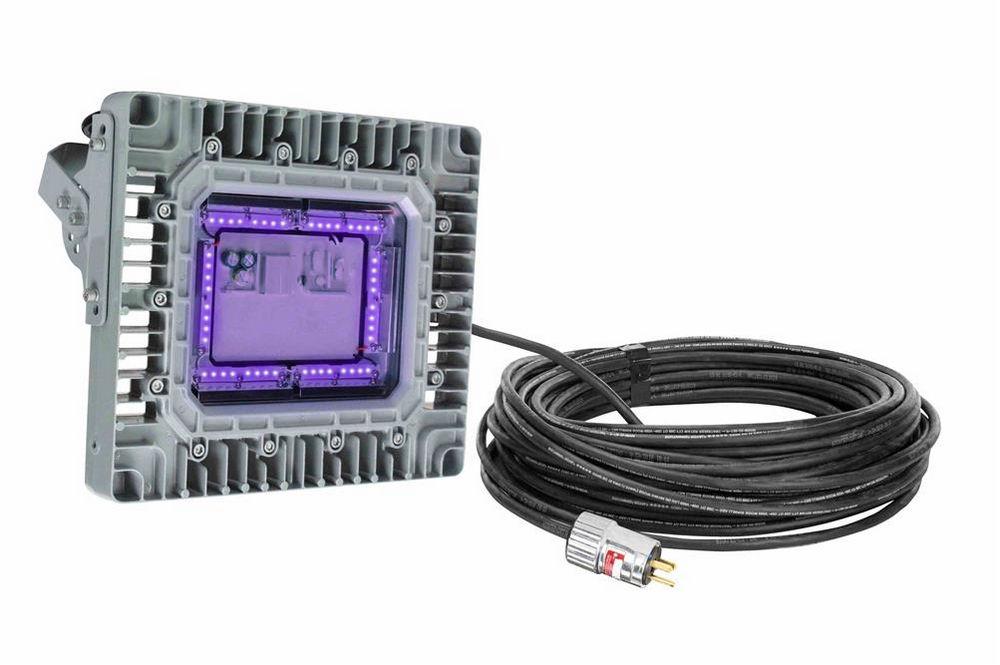

100W Explosion Proof Ultraviolet LED Light Fixture - C1D1 - 365NM - 100' SOOW Cord w/ EXP Plug

100W Explosion Proof Ultraviolet LED Light Fixture - C1D1 - 365NM - 100' SOOW Cord w/ EXP Plug

Sold by: LARSON ELECTRONICS

| EPL-HB-100LED-RT-UVA-100C-EPP - C1D1 Ultraviolet LED Light | Ratings/Approvals |

| Lamp Type: LED | Class I, Div 1, Groups C,D |

| Dimensions: 14"-H x 16"-W 5"-D | Class I, Div 2, Groups A,B,C,D |

| Weight: 28lbs | Class II, Div 1 & 2, Groups E,F,G |

| Voltage: 100-277 Volts AC, 50/60Hz | Class III |

| Total Watts: 100W | T5 Temperature Rating |

| Total Intensity: 35,000 mW | Certified to UL844 and C22.2 Standards |

| Efficiency: 350 mW/w | Paint Spray Booth Approved |

| Lighting Configuration: Flood Pattern | LEL Approved |

| Lamp Life: 50,000+ Hours | IP67 Rated Waterproof |

| Color: Ultraviolet- 365NM | Multiple Driver Banks |

| Wavelength Curve: 350-400NM - Peak @ 365NM | 80% Intensity Retention after 50,000 Hours |

| Temp Rating: T5 -50C to +65C | Â |

| Mounting: 3/4€ Pendant and Swivel Mount | |

| Cord: 100` 16/3 SOOW Cord w/ EXP Cord Cap | |

| Cord Cap Options: 5-15P, 5-20P, 6-20P | Toll Free:Â 1-800-369-6671 |

| Â | Intl:Â 1-214-616-6180 |

| Â | Fax:Â 1-903-498-3364 |

| Â |

| The Larson Electronics EPL-HB-100LED-RT-UVA-100C-EPP Explosion Proof Ultraviolet light fixture provides operators with a powerful and energy efficient alternative to traditional hazardous location luminaries with UV cutoff filters. LED technology and compact design makes this lamp an excellent replacement upgrade option for bulky and high maintenance cost older incandescent, metal halide and high pressure sodium lights. Equipped with 100 feet of 16/3 SOOW cord and an explosion proof cord cap, this fixture uses advanced LED light technology to produce ultraviolet light and is T6 rated for hazardous locations where UV lamps are used in paint and adhesive curing, food inspection or for non-destructive testing. This Class 1 Division 1 & 2, Class 2 Division 1 & 2 explosion proof UV light fixture provides 35,000 mW of high quality ultraviolet light while drawing only 100 watts. This high output UV LED fixture provides a 4,800 µW/cm2 center beam maximum intensity at 12" while providing a minimum 2,000 µW/cm2 intensity over a 14" by 14" area. The EPL-HB-100LED-RT-UVA-100C-EPP is typically used for curing coatings or adhesives and for non-destructive testing applications. This fixture has been thoroughly tested with the DuPont line of ultraviolet curable paint and primers, accelerating the cure times over metal halide fixtures with surface temperatures as low at 55°F. The copper free aluminum alloy body is powder coated for added durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 50,000 hour rated lifespan with 80% intensity retention. Light weight and a low profile make this unit an attractive alternative to larger and heavier older fixtures and requires less hardware to install. This fixture can operate on voltages ranging from 120V-277V 50/60Hz and is ETL approved for use in hazardous environments, paint spray booths, wet environments, and areas where UV lamps are used in paint and adhesive curing, food inspection, and for non-destructive testing. | |||||||||||||||||||||

|

|

|||||||||||||||||||||

The explosion proof LED light fixture features multiple LED drivers which helps to increase the operational life of the fixture. With traditional LED lights, in the event an LED array or driver fails, the entire fixture no longer illuminates. This new series of LED lamps contains twelve individual LED boards configured in a series of banks. Each bank contains two LED boards with an individual driver. In the event of a driver failure, only one bank of LEDs will be effected while the other banks will continue to operate. In the event that of an LED failure, the mating LED will continue to operate.

The EPL-HB-100LED-RT-UVA-100C-EPP uses ultraviolet LED light technology, a technology that is far better in energy saving than traditional fluorescent bulbs used for the same purposes. Traditional ultraviolet lights require a coating to block out visible light or a special composition of gases and chemicals used to create a higher concentration of ultraviolet light. This process, however, also produces many other wavelengths of light which go unused and end up as wasted energy. LED lights are unique in that they have a narrower wavelength band than traditional ultraviolet sources and therefore do not require these special coatings. As a result, LED lights do not produce unused, wasted light and therefore consume less energy than traditional UV lights on the market. LED lights have the added benefit of being capable of producing very specific wavelengths with tighter curves and are more durable and light weight as well. This eliminates harmful UV-B and UV-C wavelengths from being emitted from the light source, adding in productivity and safety during operation.

Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current applied and emitting light. With LED lights, there is no warm up time or cool down time before re-Striking and provide instant illumination when powered on, adding to the reliability of LED technology. By nature, LED light sources run significantly cooler than traditional lamps, reducing the chance of accidental burns and increased temperatures due to heat emissions. This solid state design of light emitting diodes provides a more reliable, stable, durable, and energy efficient light source over traditional lighting.

|

|||||||||||||||||||||

|

|||||||||||||||||||||

Shipping and delivery Information

Shipping and delivery Information

Estimated delivery times range from same day to 2 weeks, depending on your location, the product ordered and stock availability. External factors such as courier network disruptions can also impact delivery timelines. PuriLite strives to ship your purchase in the shortest possible time using industry standard courier services.

For any questions related to shipping and delivery, please call +1-647-254-9757, email us at info@purilite.ca or chat with us by clicking on the chat icon at the bottom right of this page.

The PuriLite Peace of Mind 30-day money back guarantee

The PuriLite Peace of Mind 30-day money back guarantee

Enjoy our peace of mind 30-day money back guarantee on all products. If you are not satisfied with any of our products, your item is eligible for return within 30 days of purchase, subject to the terms & conditions below.

1. Goods must be returned in new & unused conditions with all original packaging. Do not write or put stickers on original packaging.

2. Any shipping charges incurred by Purilite to ship the product to your destination and returns from your location to our warehouse, in case of refused shipments, are non-refundable.

3. Depending on the product purchased, the client will be responsible for shipping product back to our warehouses.

4. Restocking fees map apply once inspected at our warehouse. All credits are subject to final inspection of good upon arrival at our destination.

5. Defective products are eligible for return.

If you purchased a product and did not receive the parcel, please contact us at sales@purilite.ca and we would be happy to assist you right away! PuriLite uses secure and well-established carriers (such as Canada Post, FedEx, Purolator, UPS etc.) to ensure your purchase is delivered successfully to your doorstep. All items are delivered with a tracking ID and are traceable. If your parcel was indeed not received, we will issue back a 100% refund.

Shop with confidence knowing that your purchase is protected, and your peace of mind is our commitment. Thank you for choosing PuriLite!

Sustainability & Ethical Sourcing

Sustainability & Ethical Sourcing

At PuriLite, we believe innovation should go hand-in-hand with responsibility. That’s why we’re committed to creating products that not only perform well but are also thoughtfully made with the planet and people in mind.

♻️ Sustainable Practices

- We prioritize durable materials that extend the product life cycle and reduce waste.

- Where possible, our packaging is made from recyclable or minimal-waste materials, helping to reduce environmental impact.

- Many of our electronic products are designed with energy efficiency in mind to minimize power consumption.

🤝 Ethical Sourcing

- We partner with manufacturers who fillow fair labor practices, ensuring safe working conditions and fair wages for their workers.

- All suppliers are carefully vetted for compliance with environmental and ethical standards.

- We avoid the use of materials from conflict zones and work to reduce the environmental footprint across our supply chain.

🌍 Our Ongoing Commitment

We're actively exploring new ways to improve—from using eco-certified components to optimizing our logistics for a lower carbon footprint. Every small step counts, and we’re committed to doing our part in building a more sustainable future.